Harley Davidson Exhaust Bolt Torque

This might be a bit high but because it is a steel stud in an aluminum head it could serve as a guide to a maximum limit.

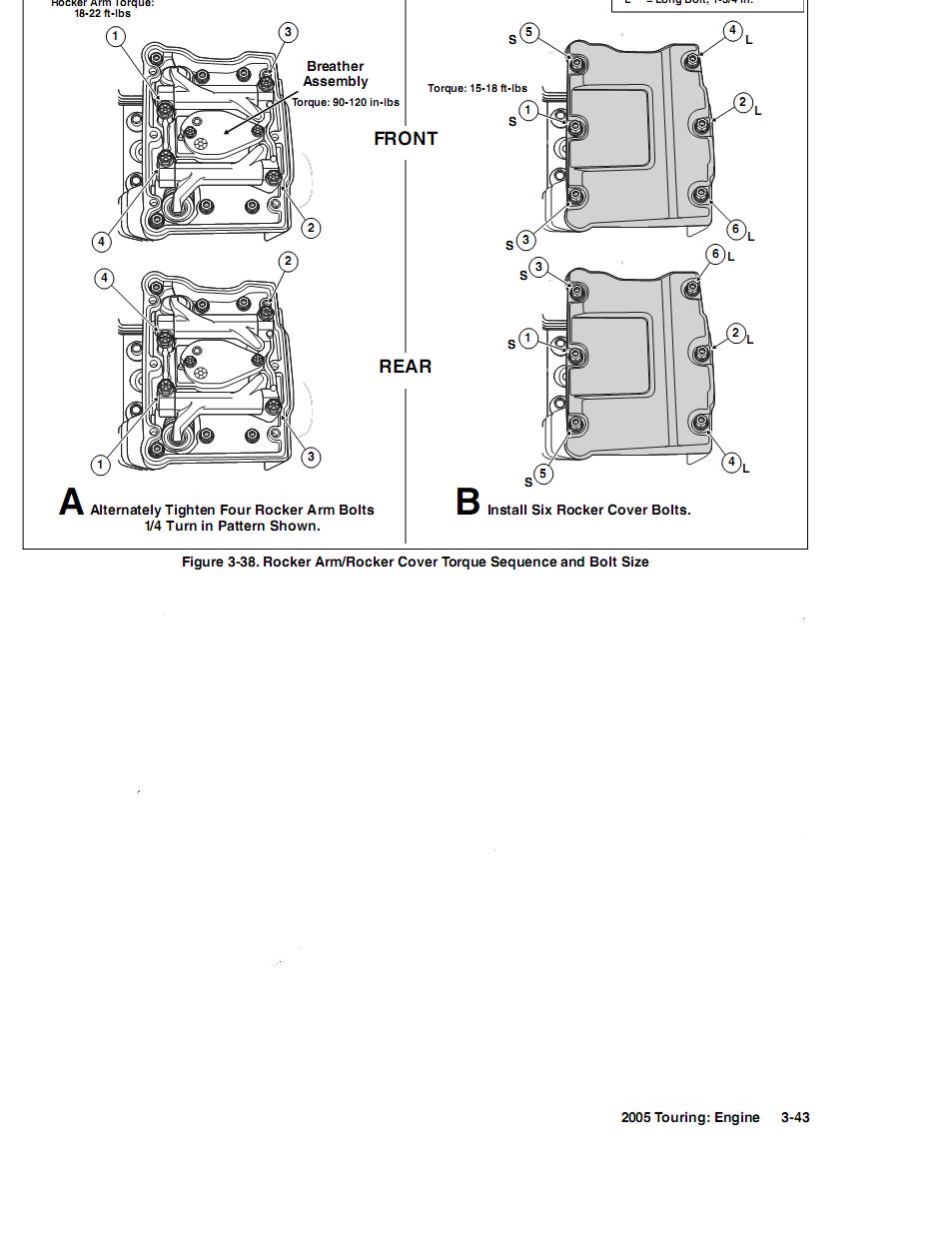

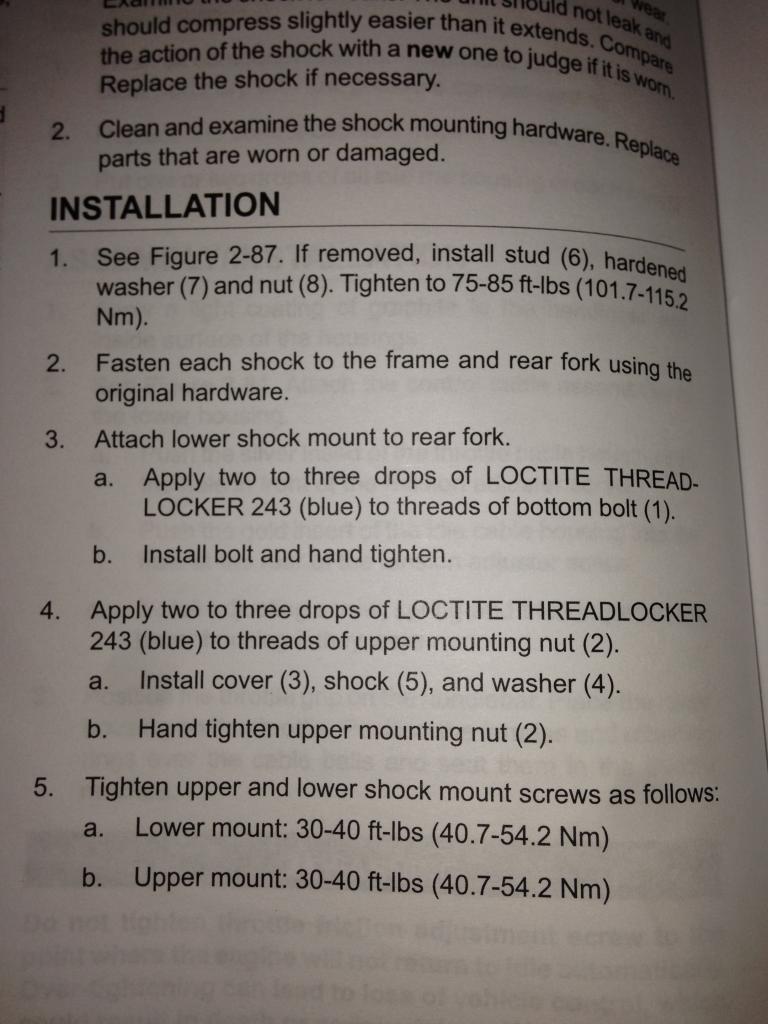

Harley davidson exhaust bolt torque. The torque values I found for that size thread gives 8 ftlbs for a steel to steel interface. First you should pre-load the bolts to about 16 foot-pounds. Then remove the rear exhaust pipe mounting bolts.

Not to mention the pain in the azz if you snap a stud off in the head a few years from now. 516 - 19 ft. Front Exhaust is Green.

85 cc bathtub Cam system - Twin cams chain driven with spring loaded tensioners Max. Route the oxygen sensor wiring back to their respective plugs and secure with wire ties as necessary. Torque - 86 ft-lbs 1088 Nm 3500 rpm chrome duals exhaust Bore - 375 in.

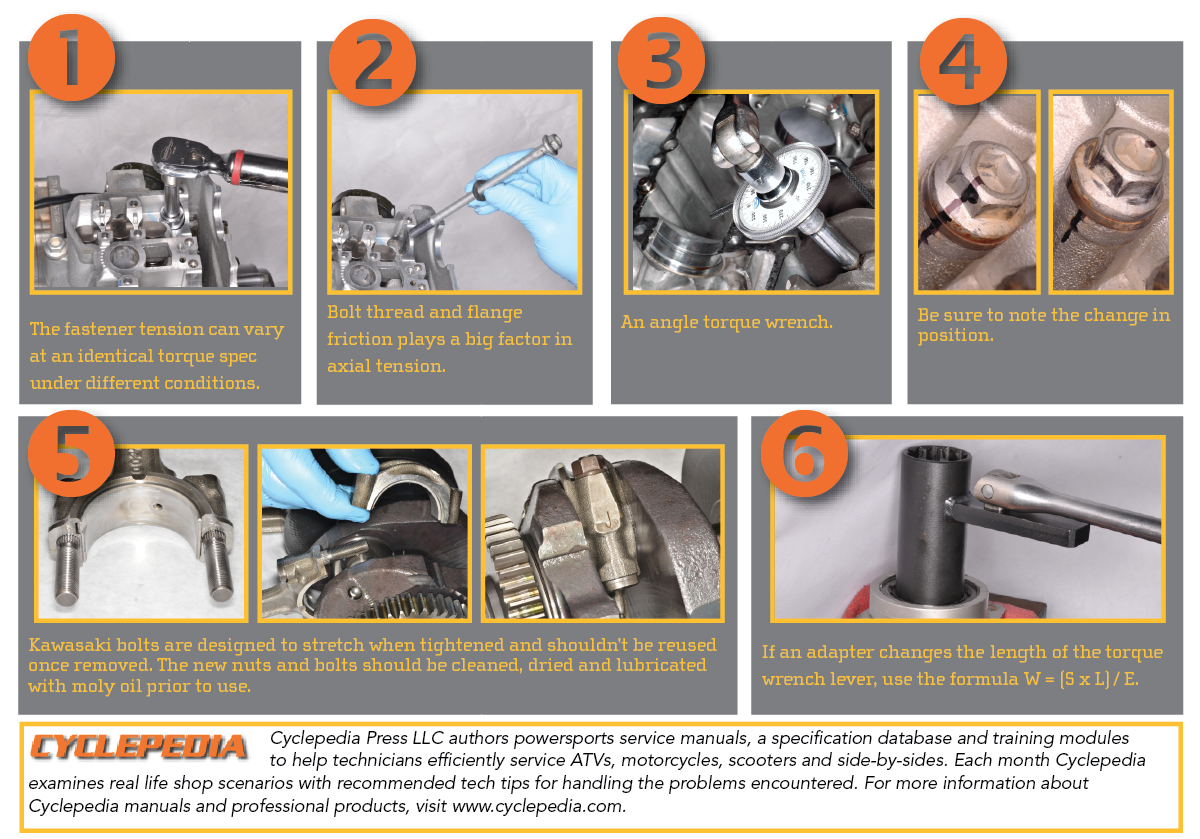

You really should get the manual specific to your model. Harleys head-bolt torque method harkens back to a time when torque specifications were less scientific. Just watched this video about checking the bolt torque for exhaust brackets for aftermarket exhaust.

You may have to remove the heat shields in order to access the bolts on all the flanges and use antiseize compound all that heat and corrosion will make things tough the next time. You get a feel for the torque by taking a torque wrench and turning to the specified torque on something else to get the feel for the specified torque. Be careful not to over-tighten.

Your yearmodel bike might not have the same torque values as mine or somebody elses. Reveal the Exhaust Pipe Opening. Then you torque the specific part.